Reinvented Toilet Technology in Development

Zyclone Cube | SCG Chemicals Co., LTD

Biological and Electrochemical Reinvented Toilet

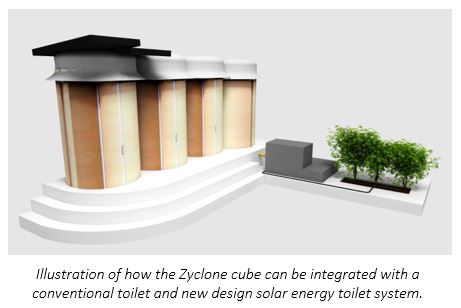

Integrating with a conventional flushing toilet, the Zyclone Cube is designed for efficiently separating and effectively treating both solid and liquid fractions. The unique Zyclone shape achieves liquid separation at greater than 98%. The solids fraction is dropped into a screw heating device that operates intermittently in dehumidifying and inactivating pathogenic contents. The liquid is further treated by integrated absorptive media (e.g. modified soil and zeolite) in a series of anaerobic aerobic, and anoxic chambers prior to a final step of electrochemical disinfection.

- Toilet system (1-4 toilets per one unit)

- Pout flush (1.5 Liters) up to 130 users/day

- Flushing (3.0 Liters) up to 70 users/day

- Ability to retrofit in existing system

- Encourages environmentally friendly fecal sludge management (FSM) practices in areas with limited access to FSM services or with temporary solutions (e.g. camp, natural sites, temporary festive event, refugee camp, medical triage)

Status of Development

- Original design by AIT initially tested in Thailand

- Design then adapted by SCG Chemicals to meet ISO 30500 standards and cost-efficient manufacturing

- 50 initial prototype units to be tested in Thailand in 2019

Use Cases

- Household and public toilets: Designed to serve 4 toilets stall processing the waste of 130 users per day

Product is Appropriate For:

| 130 | $0.10 | 15 |

|---|---|---|

| Capacity (users/day) | Est. Cost ($/users/day) | Life Expectancy (Years) |

How Does it Work?

Frontend

User encounters a conventional flush toilet. It is possible to adapt to both a pedestal and squat plate flush interface.

Urine/Feces Separation

The unique shape of the Zyclone results in a solid/liquid separation effectiveness of greater than 98%.

Liquid Processing

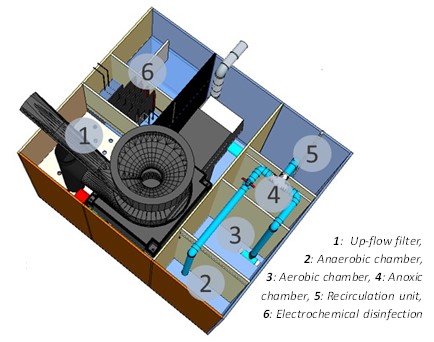

The separated liquid is firstly filtered in a plastic media chamber (1) to remove coarse solid particles. The next two chambers (2, 3) are filled with synthesized media at 2cm and 1cm diameter, respectively. In the anaerobic chamber (2), the organic loading is reduced prior to an aerobic chamber (3) equipped with microbubble aeration that further removes COD, TN, and TP contents. In the next chamber (4), TN is greatly reduced by zeolite media in an anoxic condition. Chamber 5 (5) is designed to recirculate the treated liquid to the anaerobic chamber (2) in order to increase the overall treatment performance. The final chamber (6) is equipped with electrochemical electrodes that inactivate the pathogens remained in liquid prior to discharge.

Solids Processing

The separated fresh fecal matter (solid) is collected in a chamber located below the Zyclone separator and be disinfected and reduced the moisture content by screw heating device. The heating device could inactivate helminths 4-5 log values and E. coli by 6 log value.

Power System

The system requires electricity.

Inputs

Does the system require an external source of electricity?

Yes

Does the system require the use of water?

Yes, flush water

Does the system require any other "consumable" inputs?

Yes, media

Outputs

How much energy will be recovered?

None

How much water will be recovered?

200 liters/day

How much fertilizer or other byproducts will be produced?

10kg solids/month

Treatment

Solids Treatment Thermal disinfection

Liquid Treatment Biological and electrochemical

Pathogen treatment success? Confirmed total pathogen removal

Are chemical processes used? Yes

Are mechanical processes being used? Yes, separation

Are biological processes being used? Yes

Does the system require any off-site or additional processing? No

Business Considerations

Estimated daily operating cost $0.10 USD/day

Estimated capex (not available)

Size L 1.45m x W 1.25m x H 1.35m

Maintenance Requirements

Media to be replaced every 3 years

Electrodes to be changed every 3 years

Fertilizers to be collected every month

Life expectancy 15 years