Reinvented Toilet Technology in Development

The Empower Sanitation Platform | Duke Center for Wash-Aid

Dry Combustion Reinvented Toilet

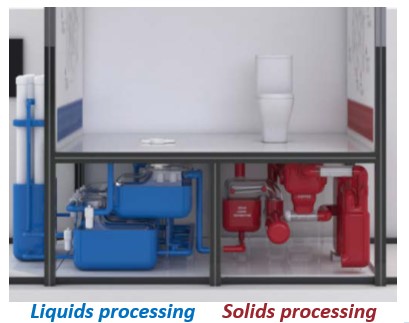

Community toilet with both liquid recycling and solids processing. The toilet is compatible with pedestal and squat plate styles. Onsite processing includes electrochemical disinfection and recycling of liquids, and drying and sterilization of solids with optional combustion. User amenities may include body wash and hand wash stations and menstrual pad dispenser and disposal options.

- User options developed through four year in-field household and community design studies

- Liquids processed via active filtration and electrochemical disinfection, meeting ISO discharge standards

- Independent solid and liquid processing modules can be paired with other technologies to create a suite of sanitation products

- Examples of new products include The Reclaimer, a liquid recycling unit, and a stand-alone menstrual waste management unit

Status of Development

- Third generation (TRL 7) prototype in active testing in Coimbatore, India and Durban, South Africa; Coimbatore testing focuses on women and girls

- Both liquid recycling and menstrual pad processing products will be tested first in India in January 2019

Use Cases

- Household and Community: Designed for 10 to 50 users per day. The processing system can be adapted to service multiple seats in a community block.

| 10 to 50 | TBD | 10 |

|---|---|---|

| Capacity (users/day) | Est. Cost ($/users/day) | Life Expectancy (Years) |

How Does it Work?

Frontend

Compatible with both pedestal and squat plate interfaces

Urine/Feces Separation

Mesh belts used for initial separation. Baffle tanks in liquid processing stream allow for additional settling of solids

Liquid Processing

(blue) Hybrid processing includes activated carbon filtration with electrochemical disinfection. A post baffle filter is used for Helminth egg removal. The disinfected liquid is recycled for flush water.

Solids Processing

(red) After initial separation, solids are dried at 90°C. Combustion option may increase solids processing capacity across multiple units

Power System

Currently power by grid power. Optional solar panels (500 W) for supplemental and off-grid energy.

Inputs

Does the system require an external source of electricity?

Yes. Requires 5-7kWh/day, currently provided through grid power (deep-cycle batteries) or 500 W photovoltaic panels.

Does the system require the use of water?

Wash and/or flush water 30L initial charge, otherwise recycled water is used in system.

Does the system require any other "consumable" inputs?

No

Outputs

How much energy will be recovered?

None. Energy is not used in process

How much water will be recovered?

10-30 L/day-excess water will be discharged after disinfection, remainder is used for flush water

How much fertilizer or other byproducts will be produced?

Sterilized dried solids may be collected or incinerated onsite.

Treatment

Liquids Electrochemical and activated carbon

Solids Thermal

Pathogen treatment success? Confirmed total pathogen removal

Are chemical processes used? Yes

Are mechanical processes being used? Yes

Are biological processes being used? No

Does the system require any off-site or additional processing? No

Business Considerations

Estimated daily operating cost (not available)

Estimated capex (not available)

Size L 1.5m x W 2.0m x H 1.25m

Maintenance Requirements Ash/dried solids emptied weekly (by user)

Life expectancy 10 years

Other Features Menstrual pad disposal