REINVENTED TOILET TECHNOLOGY IN DEVELOPMENT

CRANFIELD CIRCULAR TOILET

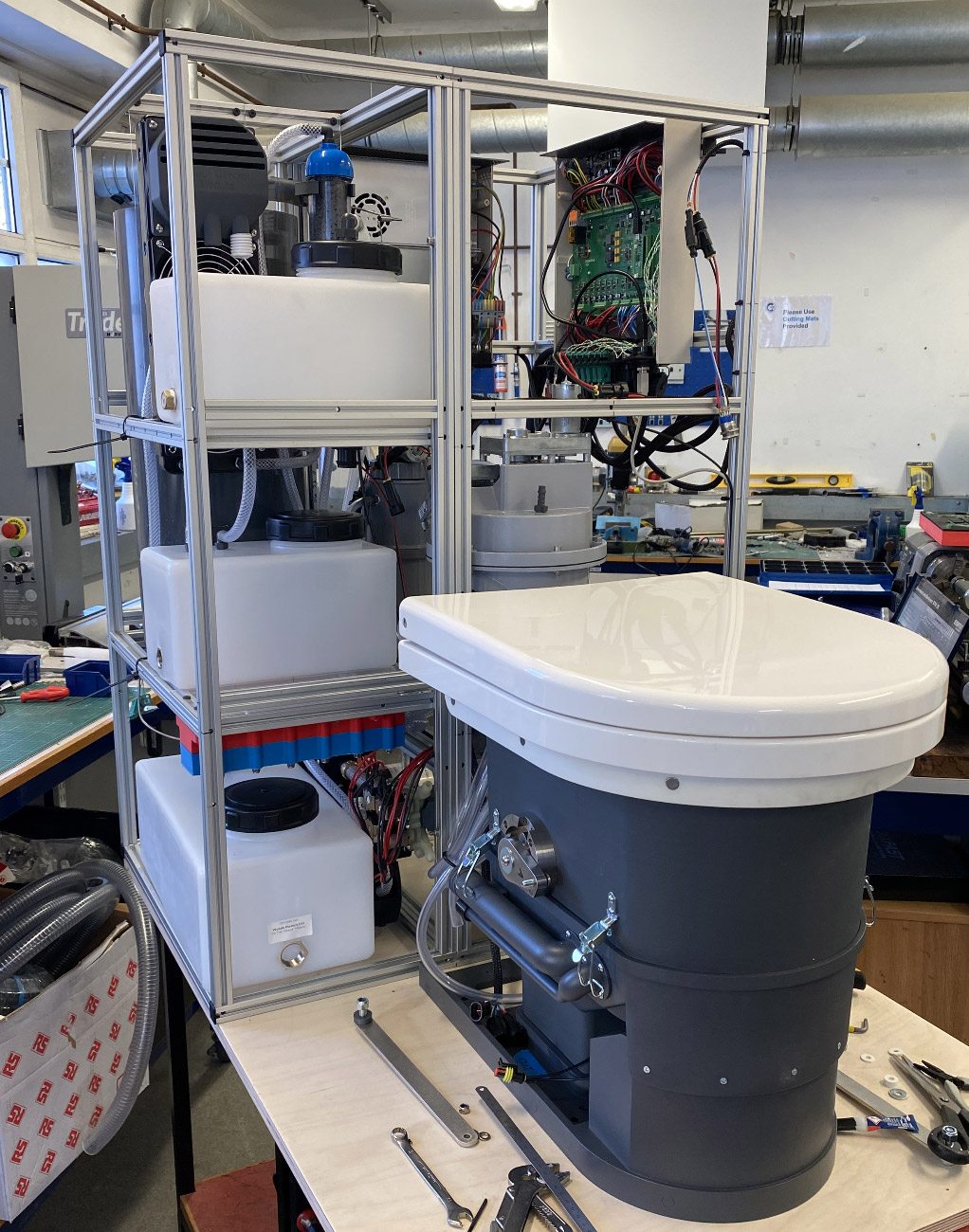

Self-contained Reinvented Toilet

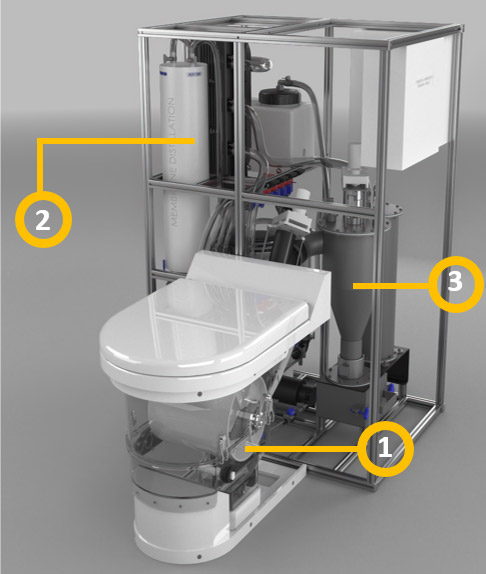

The Cranfield Circular Toilet (CCT) is a lightweight, compact, affordable, and self-contained household toilet system made up of three modular components.

Module Components:

i ) A super-low water pedestal module - with an integrated rotating bowl and jet spray clean arrangement.

ii ) A novel torrefaction solids processing module to char solid waste and ensure pathogen kill.

iii ) A compact low energy consumption membrane distillation technology for mechanical liquids processing.

Important Note: The system only requires priming with water [on startup] and automatically recycles liquids that entre or circulates around in the system thereafter with infrequent cleaning and maintenance.

- Self-contained household toilet system: for a five-person household

- Unique super-low water flush system minimizes water requirements

- Liquid processing module is highly effective for removing waterborne contaminants

- Solids processing module eliminates all microbiological pathogens within feces

- Toilet requires infrequent cleaning and maintenance

Status of Development

- Optimized subcomponent performance

- Frontend and backend component prototypes developed in Cranfield, UK

- Frontend tested in households in Durban, South Africa. Full system is now ready for extensive field trials in UK, USA, Germany, and China

Use Cases

- Household: Designed as a self-contained toilet for a five-person household

- Multi-unit: Core processing technology could be scaled for school, or public/community application

Product is Appropriate For:

| 10 | TBD | 10 |

|---|---|---|

| Capacity (users/day) | Est. Cost ($/users/day) | Life Expectancy (Years) |

How Does it Work?

Frontend

The user encounters a pedestal toilet featuring an exceptional super-low water flush system, complete with an integrated rotating bowl and jet spray cleaning mechanism.

Liquid Processing

Liquid is collected and purified for re-use in the pre-wetting and cleaning processes. Membrane distillation can achieve compliance with ISO 30500 as it is highly effective for removing waterborne contaminants. The distillate from the liquid waste treatment module is used as the spray water in the frontend, making this ideal for use in water-scarce communities, or it can be safely discharge to the environment.

Solids Processing

Solids processing module is based on low temperature torrefaction which decomposes the solid waste in an oxygen-free environment. It eliminates all microbiological pathogens within feces so as to generate a safe and biologically benign char with releasing low harmful product gases such as NOX and SOX pollutants.

Inputs

- Does the system require an external source of electricity?

Yes, with low energy consumption - Does the system require the use of water?

No. The system only requires priming with water [on startup] and automatically recycles liquids that entre or circulates around in the system. - Does the system require any other "consumable" inputs?

Certain acid wash GAC should be considered, which could be categorized as consumable due to its expected replacement within a 12-month timeframe.

Outputs

- How much energy will be recovered?

None. - How much water will be recovered?

The distillate from the liquid waste treatment module is used as the spray water in the frontend, or sent to a storage tank for later use. - How much fertilizer or other byproducts will be produced?

The torrefaction process creates a significant volume reduction of up to 50% from solids which have entered the system. Pathogen free solids are captured in a small char tray which is easily removed by the user for emptying into a household waste bin or onto the garden where is makes an ideal and safe fertilizer. Frequency of emptying depends upon usage but approximately once per 24-48 hours and is quick and easy to do.

Treatment

- Solids treatment Torrefaction

- Liquids treatment Membranes

- Pathogen treatment success?

Ensure pathogen kill - Are chemical processes used?

No - Are mechanical processes being used?

Yes - Are biological processes being used?

No - Does the system require any off-site or additional processing?

No

Business Considerations

- Estimated daily operating cost (not available)

- Estimated capex (not available)

- Size L 1.26m x W 0.75m x H 1.3m

- Maintenance Requirements

The toilet is actually a net producer of water. Treated water (Category A/B) is re-used for flushing, bowl cleaning and automated internal back-washing cycles. Excess water is allowed to weir to a suitable discharge point, e.g., drain or garden. There is no requirement for user intervention apart from periodic cleaning as per conventional toilet systems. - Life expectancy 10 years