Reinvented Toilet Technology in Development

eToilet | Eram Scientific Solutions

Electrochemical Reinvented Toilet

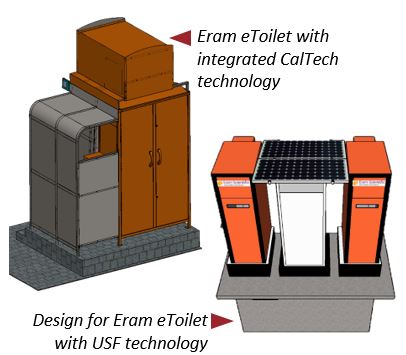

Erams Scientific's eToilet incorporates a full treatment solution by integrating the existing eToilet technology deployed in over 3500 sites with novel treatment technologies stemming from the Reinvent the Toilet Challenge. The current prototype incorporates the CalTech electrochemical reactor to process the black water and produce reusable effluent, also safe for discharge. Additional prototype incorporating the University of South Florida treatment technology is also under development.

- eToilet features automated entry and self-cleaning of toilet bowls and floors for automated and unmanned operations

- Remote monitoring capabilities

- Sensor-enabled water minimization system

- Treated water from CalTech reactor is recycled back for toilet flush and floor wash

- Multiple potential business models being explored to support scale up of treatment units

Status of Development

- eToilet with CalTech integrated treatment system prototype field testing in Coimbatore, India in late 2018 through 2019

- Additional prototypes incorporating USF technology to be built and tested in 2019

- Goal is for product availability by early 2020

Use Cases

- Single-unit: Designed as a automated self-contained, toilet unit deployed in public sites, schools, or transport centers, capable of handling up to 100 users per day.

Product is Appropriate For:

| 100 | $0.07 | 10 |

|---|---|---|

| Capacity (users/day) | Est. Cost ($/users/day) | Life Expectancy (Years) |

How Does it Work?

Frontend

Eram Scientific's eToilet, an unattended and automated self-cleaning electronic toilet cabin with remote monitoring and sensor enabled water minimization capability.

Urine/Feces Separation

No separation is required.

Liquid/Solids Processing

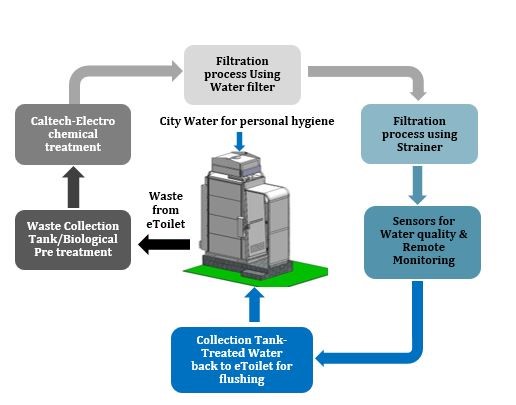

Waste stream is flushed and sent to the biological pretreatment holding tank. Waste is then pumped to the electrochemical reactor (ERC) based on the CalTech technology. The quality of the effluent following final filtration using water filters and strainer if confirmed using sensors and remote monitoring. Water is then stored for reuse as flushing water in eToilet.

Power System

Currently powered by grid power.

Inputs

Does the system require an external source of electricity?

Yes, grid electricity is required.

Does the system require the use of water?

Yes, the personal hygiene taps and faucets require water.

Does the system require any other "consumable" inputs?

No

Outputs

How much energy will be recovered?

None. Energy is used in process

How much water will be recovered?

All water used in the toilet is recycled for flushing and clearing

How much fertilizer or other byproducts will be produced?

None

Treatment

Treatment Biological pretreatment and electrochemical disinfection

Pathogen treatment success? Confirmed total pathogen removal

Are chemical processes used? Yes

Are mechanical processes being used? Yes, water filter

Are biological processes being used? Yes

Does the system require any off-site or additional processing? No

Business Considerations

Estimated daily operating cost $0.07/user/day

Estimated capex ~$13,500 USD

Size L 2.2m x W 1.7m x H 3.1m

Maintenance Requirements (not available)

Life expectancy 10 years