Reinvented Toilet Technology in Development

HTClean | Helbling with Gates Foundation

High Temperature Processing Reinvented Toilet

Helbling has been engaged by the Gates Foundation to develop HTClean, a next-generation Reinvented Toilet based on a high temperature and high pressure processing design. The toilet is being engineered specifically for the household. Intuitive visual cues on operation, maintenance, status, and usability are integrated.

- Self-sustaining toilet without water and sewage connection

- Single household system designed for 4-6 users/day, up to 10 users/day

- Vacuum flush system greatly reduces the flush water required (0.2-0.9 L)

- A unique, intuitive human machine interface (HMI)

Status of Development

- Demonstrator unit developed and lab tested in Zurich, Switzerland

- Additional prototype testing and design improvements planned starting from January 2019

Use Cases

- Household: Designed as a self-contained household unit for up to 10 users per day

- Multi-unit: Core processing technology could be scaled for school or public/community application or by installing units in each stall

Product is Appropriate For:

| 10 | TBD | 20 |

|---|---|---|

| Capacity (users/day) | Est. Cost ($/users/day) | Life Expectancy (Years) |

How Does it Work?

Frontend

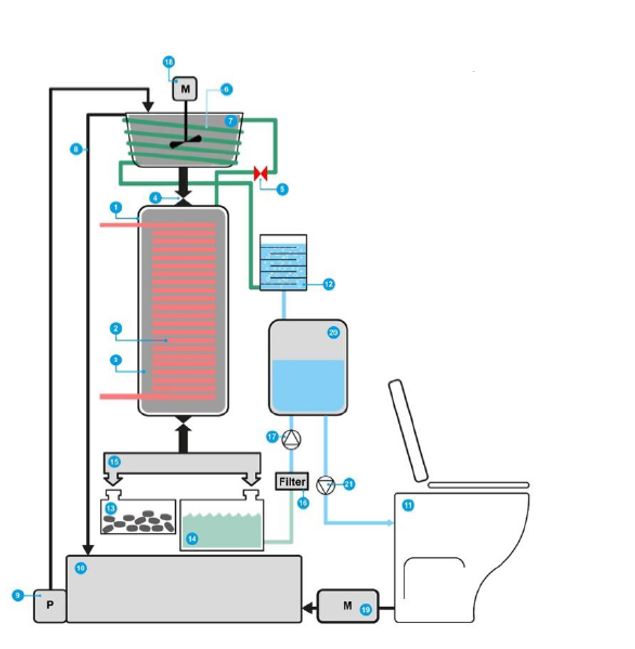

The input tank (10) is fed by the user input of the toilet (frontend, 11) through a vacuum pump including a macerator (19).

Urine/Feces Separation

Solid/liquid separation is conducted after processing by a mechanical filter press (15).

Processing

The user input is initially stored in a holding tank (10). The composited material from the storage tank is passed through a pre-heater (7), then loaded into a reactor chamber (4) and heated above 160°C* (2), at a pressure up to 25 bar* . After cooling the reactor is discharged and solids and liquids are separated (15), resulting in a small filter 'cake' (13). The produced liquid is retained (14) and then cleaned for use in the toilet flushing system. Water vapor released from the reactor after processing is used for pre-heating (6) quenched in a bubble tank (12). The quenched water in (12) is also cleaned and combined with the flush water (20).

* Optimum operational conditions are currently being identified

Inputs

Does the system require an external source of electricity?

Yes

Does the system require the use of water?

No, water is recycled within the system

Does the system require any other "consumable" inputs?

No

Outputs

How much energy will be recovered?

To be determined when optimal operation conditions are finalized

How much water will be recovered?

The flush water is a closed loop. Any excess water collected, due to urine deposits will be discharged

How much fertilizer or other byproducts will be produced?

20g filter cake/user/day

Treatment

Treats Solids and liquids combined

Pathogen treatment success? Total pathogen removal

Are chemical processes used? Yes

Are mechanical processes being used? Yes, water filter

Are biological processes being used? No

Does the system require any off-site or additional processing? No

Business Considerations

Estimated daily operating cost (not available)

Estimated capex (not available)

Size L 1.2m x W 1.0m x H 1.9m

Maintenance Requirements Non-hazardous, non-odorous, solid waste cakes and excess liquids to be regularly disposed by user.

Life expectancy 20 years