Reinvented Toilet Technology in Development

Eco-San Toilet | Eco-San

Electrochemical Reinvented Toilet

Eco-San is one of the leading developers of the CalTech technology, focusing on school and public toilets, and containerized toilet units. The backend processing technology capitalizes on anaerobic digestion of solids and an electrolysis system to convert waste into water, hydrogen, and solid fertilizer. Eco-San is piloting three units in China, and two in South Africa. Eco-San's sister company, Yixing, Entrustech, is producing and reducing the cost of the electrodes that drive the electrolysis treatment process to make available to all partners.

- Design can be fully containerized, or with separate digestion tank

- Patented electrochemical cells process mixed wastewater

- Can recycle process effluent as toilet flush water, notable in water scarce areas

- Compatible with any type of flush toilets (squat pan, western style, urinals, etc.)

Status of Development

- Eco-San is piloting three units in China, two at tourist locations: a park and a temple, and one at an elementary school

- Two units are being commissioned as community ablution blocks in Durban, South Africa

Use Cases

- Multi-unit: Core processing technology scalable for school, or public/community application; capable of servicing 50-800 users per day with one system.

Product is Appropriate For:

| 800 | $0.02 | 5-10 |

|---|---|---|

| Capacity (flushes/day) | Est. Cost ($/flush/day) | Life Expectancy (Years) |

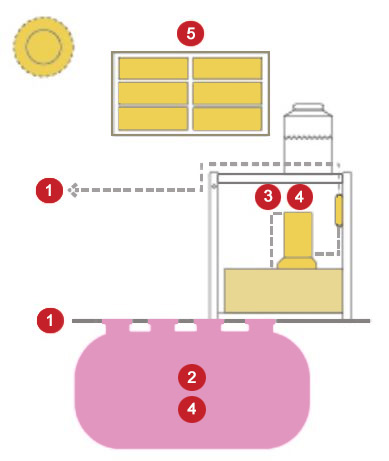

How Does it Work?

Frontend

Includes up to 8 toilets and urinals located near the backend processing components.

Urine/Feces Separation

No urine/feces separation. Mixed waste passively settles in a separation tank with anaerobic digestion. Active pre-processing with an anaerobic/aerobic system is available.

Liquid Processing

An elctrochemical system oxidizes the effluent from the septic tank and biological treatment unit at a semiconductor anode and water is reduced at the metal cathode to form H2. Chloride, from table salt, can be added if there is an insufficient amount in the waste. Membrane microfiltration is currently included for polishing the final effluent.

Solids Processing

Feces are macerated with the urine and flush water, all are processed together. Undigested solids that have settled in the septic tank are estimated to require evacuation once a year.

Power System

Solar panels, with energy storage via battery stack, and/or grid electricity. Estimated 18kwh required per m3.

Inputs

Does the system require an external source of electricity?

Yes. Provided by solar panels or grid

Does the system require the use of water?

No

Does the system require any other "consumable" inputs?

No

Outputs

How much energy will be recovered?

None. Energy is used in process

How much water will be recovered?

4-5m3/day usable, not portable

How much fertilizer or other byproducts will be produced?

1 ton per year

Models

b-CRT 20i 31

b-CRT 2x20 32

b-CRT 40 33

b-CRT B 34

b-HRT (ECR) 35

b-HRT (UV) 36

Treatment

Treats Solids and liquids

Pathogen treatment success? Confirmed total pathogen removal

Are chemical processes used? Yes

Are mechanical processes being used? Yes

Are biological processes being used? Yes

Does the system require any off-site or additional processing? No

Business Considerations

Estimated daily operating cost $0.02/flush/day

Estimated capex (not available)

Size L 12m x W 2.2m x H 2.7m

Maintenance Requirements Solid wastes to be emptied half a year (by user). Membrane filters to be replaced once a quarter.

Life expectancy 10 years