Reinvented Toilet Technology in Development

The Toronto Toilet | University of Toronto (UT)

Dry combustion Reinvented Toilet

A household-scale system with solid and liquid disinfection in the backend. In the frontend, feces and urine/wash water are mechanically separated by a specifically designed mechanism that can be attached to standard squat plates. Attachment to pedestals is also possible. Dewatered fecal material is then mixed with granular particles and smoldered. Catalytic conversion of the generated is used to dry incoming fecal material in situ, and thermally disinfected liquid waste.

- Self-sustaining smoldering technology, under development since 2011, with TRL 4 results published in the journal Fuel in 2015

- Continuous smoldering process for processing of fecal matter and consistent heat production

- Catalytic conversion of the generated pyrolysis gases supplies additions heat, and mitigates emissions

Status of Development

- System integration work has led to iterative development of functional prototypes for laboratory testing in Toronto, and multiple field tests in Coimbatore, India with local workers user group.

Use Cases

- Household: Designed as a self-contained, household unit, ranging from 5 to 20 users, accommodates variable input rates

- Multi-unit: Can be scaled p to multi-stall community applications with one front end per stall, and a shared processing stall.

Product is Appropriate For:

| 5+ | $0.07 | 10-15 |

|---|---|---|

| Capacity (users/day) | Est. Cost ($/users/day) | Life Expectancy (Years) |

How Does it Work?

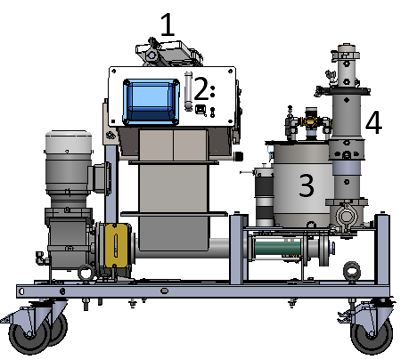

Frontend

Currently used with a standard squat plate. Can be adapted to a pedestal.

Urine/Feces Separation

Multiple gravity-based solid/liquid separation designs have been evaluated and field tested. Effective solid/liquid separation is achieved without modifying user behavior.

Liquid Processing

Liquid pasteurization is achieved by recovering the heat captured in steam during solid drying process. Further effluent treatment is intended to be adopted from other projects being conducted in the BMGF portfolio.

Solids Processing

Solid fecal material (fuel) is transferred via a pump and is injected into a column where it is in-situ mixed with granular beads which are still hot from the preceding smoldering cycle. Once the mixing/drying process concludes, air is introduced and smoldering begins. Post smoldering gases pass through a catalyst for further treatment and heat generation.

Power System

Solar panels or other off-grid energy source may be used to supply the <200 watts per day required. The aspirational goal that projections show is possible is to achieve a power requirement low enough to fit within the capacity of solar or other off-grid home systems that are common in many regions.

Inputs

Does the system require an external source of electricity?

Yes, solar panels or other power source

Does the system require the use of water?

Not required. Accepts 30L flush/wash water

Does the system require any other "consumable" inputs?

No

Outputs

How much energy will be recovered?

None, energy is used in process

How much water will be recovered?

10-50 liters/day, not potable

How much fertilizer or other byproducts will be produced?

10g ash per person, per day produced by solids processing, emptied monthly by user

Treatment

Solids Thermal processing (0.6-3kg/day capacity)

Liquids Pasteurization with 35 L/day capacity

Pathogen treatment success? Confirmed total pathogen removal

Are chemical processes used? Yes

Are mechanical processes being used? Yes

Are biological processes being used? No

Does the system require any off-site or additional processing? No

Business Considerations

Estimated daily operating cost $0.07/user/day (initial estimate based on electricity use and six users)

Estimated capex (not available)

Size L 1.7m x W 1.5m x H 1.0m

Maintenance Requirements Solids (ash) to be emptied monthly by user

Life expectancy 10-15 years

Other features Catalytic conversion of outlet air from smoldering process to reduce