Reinvented Toilet Technology in Development

Oystra | Crane Engineering

Mobile Septage Treatment System

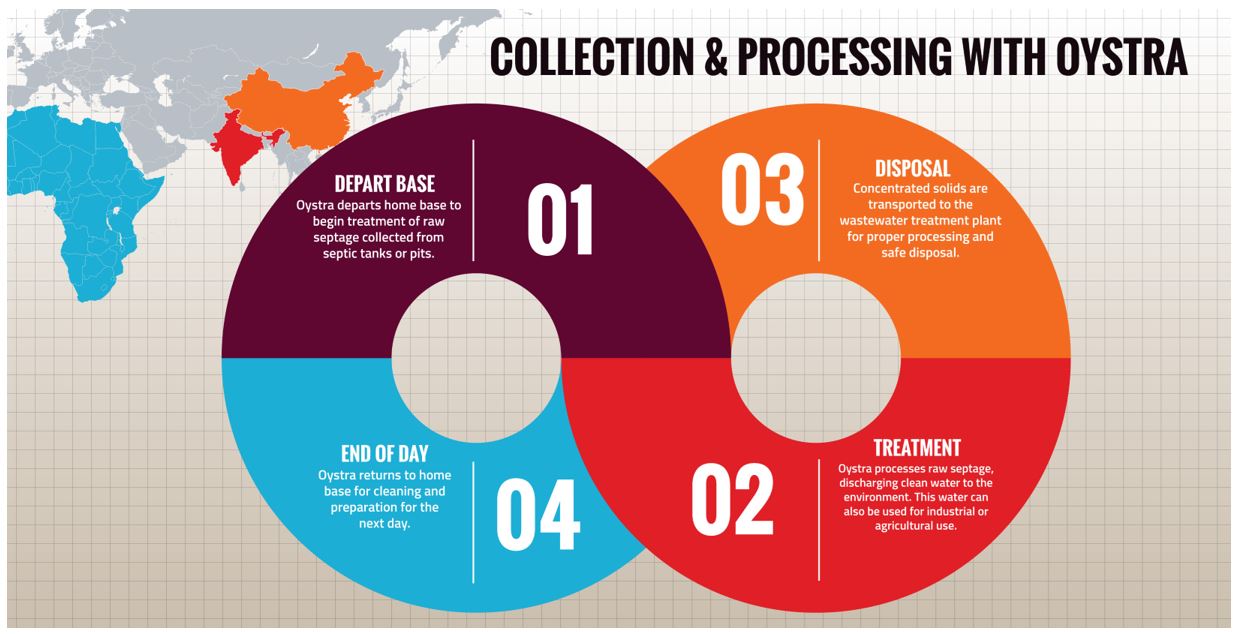

The Oystra Mobile Septage Treatment System (MSTS) is a new sanitation system that processes human fecal sludge into non-potable water for agricultural or industrial use or safe discharge. Oystra is a truck-mounted dewatering system for use in areas like dense urban settlements where poor sanitation poses the greatest risks to human health. The latest generation prototype will be more cost effective, transportable, and easier to maneuver in crowded informal settlements than traditional septage collection methods.

- Makes septic tank emptying and treatment safer and less expensive

- Pre-processes the septage from pit latrines or septic tanks to discharge clean, safe water

- Results in reduced solids volume to transport to treatment, therefore reducing transport cost

Status of Development

- In 2016, Crane built the initial Oystra Mobile Septage Treatment System (MSTS) prototype and tested locally in 2017

- The second generation prototype is complete and began field testing in October 2018

Use Cases

- Pit and tank emptiers: Designed to be used by pit/tank emptiers who collect and transport septage from containment sites to treatment facilities

Product is Appropriate For:

| 3 L/S | TBD | 20 |

|---|---|---|

| Capacity (users/day) | Est. Cost ($/users/day) | Life Expectancy (Years) |

How Does it Work?

Inputs

Does the system require an external source of electricity?

Yes. Currently powered by truck-mounted diesel generator ( <60kW steady state)

Does the system require the use of water?

No

Does the system require any other "consumable" inputs?

Diesel fuel

Outputs

How much energy will be recovered?

None. Energy is used in process

How much water will be recovered?

50-80% of intake volume discharged as safe industrial or agricultural water

How much fertilizer or other byproducts will be produced?

None

Treatment

Liquid Separated, treated, then discharged

Solids Not treated

Are chemical processes used? No

Are biological processes being used? No

Does the system require any off-site or additional processing? Yes. Concentrated septage to be transported to treatment facility

Business Considerations

Estimated daily operating cost (not available)

Estimated capex (not available)

Size H 3.2m x W 2.2m x L 4.5m (processor)

H 2.8m x W 2.4m x L 9.4m (with truck)

Maintenance Requirements Filters to be replaced every 6-12 months, daily cleaning after shift

Life expectancy 20 years