Reinvented Toilet Technology in Development

Recycling Toilet | Clear

Biological Reinvented Toilet

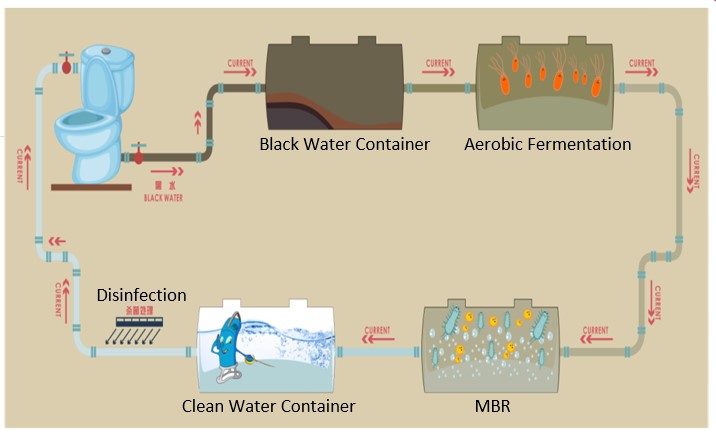

The Clear toilet uses a full-water cycling process for treatment of the sewage. A rain water collecting system can also replenish the water to the processor for self-renewal. Blackwater from the toilet is pumped up to the sewage processor for treatment and then recycled to the storage tank for flushing. An advanced unique Biofilm-MBR treatment process is employed as the core technology for treatment, producing a stable and clean effluent that is further disinfected to ensure safety of the effluent for reuse.

- Current design has four stalls and three urinals and can serve up to 1000 users/day

- Ability to operate in remote, or water-scarce conditions where there is not existing sanitation solutions such as sewers

- Wifi and media player features available

Status of Development

- Clear prototype development and testing complete in China

- Over 100 units have been sold and are in operation at sites across China

Use Cases

- Household: Technology could potentially scaled down to serve as a single household unit, up to 10 users per day

- Multi-unit: Design of system is most readily applicable to tourism sites, school, or public/community applications

Product is Appropriate For:

| 1000 | $0.03 | 10 |

|---|---|---|

| Capacity (users/day)

Front end + backend unit:

Backend units only:

|

Est. Cost ($/users/day) | Life Expectancy (Years) |

How Does it Work?

Frontend

Processing

Initially treated with physical precipitation. A special aerobic media is placed in the aerobic reactor and proprietary bacteria, specifically developed for treating wastewater, is attached on the media as a biofilm. This biofilm can effectively biodegrade more than 50% of the organic pollutants and reduce its concentration.

The wastewater is then treated by a MBR (membrane biological reactor) to separate pollutants in large size, which can be refluxed in the biodegrade process, producing clean water. Finally, the produced clean water is further disinfected via UV to kill all bacteria in the water.

Power System

The system requires external power either from grid electricity, or from solar panels. Estimated requirements is 5.65kWh/day.

Inputs

Does the system require an external source of electricity?

Yes. Currently either grid or solar panels

Does the system require the use of water?

Yes. Rainwater collection is required for startup only. Flush water is recycled.

Does the system require any other "consumable" inputs?

No

Outputs

How much energy will be recovered?

None. Energy is used in process

How much water will be recovered?

Water is recycled to be self-sustaining

How much fertilizer or other byproducts will be produced?

None

Treatment

Treats solid and liquids

Pathogen treatment success? Confirmed total pathogen removal

Are chemical processes used? Yes

Are biological processes being used? Yes

Does the system require any off-site or additional processing? Yes. Solids are required to clear every year

Business Considerations

Estimated daily operating cost $0.03/user/day

Estimated capex $50,000 (TT-1 model)

Size L 6.06m x W 5.96m x H 5.04m

Clear modular and pre-fabricated units can be installed in parallel.

Maintenance Requirements Membranes to be monitored and replaced as needed every two years. Solids may need to be emptied every year.

Life expectancy 10 years