Reinvented Toilet Technology in Development

NEWgenerator | Univ. of South Florida (USF)

Biological and Physicochemical Reinvented Toilet

The NEWgenerator is a compact, portable, and modular resource recovery machine that eliminates waste while recovering fertilizer nutrients, renewable energy, and clean water. The system uses an anaerobic baffled reactor design followed by a nanomembrane filter operated at sub-critical water flux to extend the longevity. Permeate from the filter is treated for reuse as flush water by electrochemical chlorine production from table salt.

- Anaerobic membrane bioreactor processes solid and liquid in a single, dilute waste stream

- Minerals and nutrients are removed from the wastewater by a hydroponic/biosorption system

- Biogas from waste product digestion is collected for use outside of the system (e.g. cooking/heating)

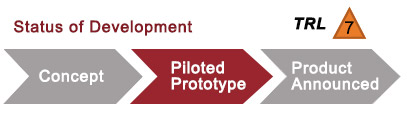

Status of Development

- Pilots in Kerala, India (2016) and in an informal settlement in Durban, South Africa (Fall 2018)

- A next-generation, high capacity unit (1000 uses/day) to be tested in South Africa in 2019

Use Cases

Scalable system from single household (less than 10 users) and up to 1000+ users a day. Current design for 300 uses/day, or ~60 users

- Multi-unit: As an exterior system, most common use cases include community toilets, schools, and multi-unit dwellings.

Product is Appropriate For:

| 60+ | $0.09 | 15+ |

|---|---|---|

| Capacity (users/day) | Est. Cost ($/users/day) | Life Expectancy (Years) |

How Does it Work?

Frontend

Agnostic to user interface can be paired with a variety of designs.

Urine/Feces Separation

No separation is required, urine, feces, and wash/flush water are processed as a single stream.

Liquid Processing

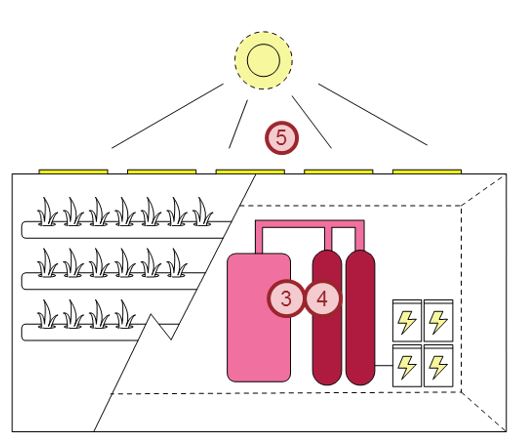

Mixed waste enters an anaerobic membrane bioreactor (AnMBR). Liquid is filtered with a commercially available nanomembrane, operated at sub-critical flux to optimize longevity of the membrane. Biosorption and hydroponic processing is used to remove additional organics and minerals. Electro-chlorination is the final polishing step.

Solids Processing

Mixed waste stream (TSS range 100-15,000mg/L) is processed by an anaerobic microbial baffled reactor, where the organic materials are digested. Residual, undegraded solids will need to be removed; modeling indicated every 6-18 months, depending on waste composition.

Power System

Currently using solar panels to charge deep-cycle batteries that power the system. Biogas generated is dependent on strength of the influent COD and can be used for various uses such as heating and cooking fuel. Estimated requirement of 0.5-1.7kWh per day.

Inputs

Does the system require an external source of electricity?

Yes, supplied by solar panels

Does the system require the use of water?

Yes, small input required to make up for any losses in system

Does the system require any other "consumable" inputs?

Yes, salt for electrochlorination

Outputs

How much energy will be recovered?

3kWh/d (as biogas) at 800mg COD/L

How much water will be recovered?

Up to 100% of influent can be recycled for reuse

How much fertilizer or other byproducts will be produced?

N, P recovered for onsite horticulture

Treatment

Solids Treatment Yes, anaerobic digestion

Liquid Treatment Yes, nanomembrane filtration followed by electrochlorination

Pathogen treatment success? Confirmed total pathogen removal

Are chemical processes used? Yes

Are mechanical processes being used? No

Are biological processes being used? Yes

Does the system require any off-site or additional processing? No

Business Considerations

Estimated daily operating cost $4-5 USD

Estimated capex $45,000 USD (prototype)

Size L 2.4m x W 1.5m x H 2.4m

Maintenance Requirements

Leveling tank cleaning every 6-18 months; prevenitive maintenance every 6 months

Life expectancy 15+ years